How to Choose the Right Mesh for Your Security Door

Choosing a security door isn’t just about the frame or locks — it’s about the mesh.

That fine weave of metal between you and the outside world is what determines whether your door can truly stop an intruder, withstand the elements, and still let your home breathe.

There are several types of mesh used in “security” or “screen” doors, but not all are equal.

Understanding the differences — in material, weave, and finish — will help you choose a door that performs like armor while looking like architecture.

Why Mesh Matters

The mesh serves three critical functions:

Barrier Strength: It resists cutting, prying, and impact.

Visibility & Airflow: It allows you to see out and feel ventilation without losing protection.

Durability: It must survive years of UV exposure, rain, and dust without corroding or stretching.

A strong frame is worthless if the mesh fails — and cheap mesh is often the first thing to go.

The Three Main Mesh Materials

If your goal is genuine forced-entry protection, you can rule out fiberglass and aluminum right away.

Only stainless-steel mesh passes internationally recognized impact and knife-shear tests.

Understanding Mesh Grades: 304 vs. 316

Both 304 and 316 stainless steel are strong, but their chemical composition makes a huge difference outdoors.

304 Stainless Steel:

Contains chromium and nickel for corrosion resistance. Performs well inland but can develop surface rust in salty, humid, or dusty environments.316 Marine-Grade Stainless Steel:

Adds molybdenum (2–3%), which dramatically improves resistance to chlorides and oxidation.

Used in coastal architecture, marine vessels, and medical equipment for its long-term stability.

Bottom line:

If you live anywhere near the ocean, in desert climates with high mineral dust, or want the longest lifespan possible, 316 stainless steel is the superior choice.

Mesh Thickness and Tensile Strength

Mesh performance isn’t only about alloy — it’s about wire thickness and tensile strength.

Most security meshes range from 0.8 to 1.0 mm wire diameter.

Premium meshes, like those used by Boss Security Screens, achieve tensile strengths above 900 MPa (megapascals) — stronger than automotive steel panels.

This allows them to withstand repeated 220-joule impacts, equivalent to the force of a full kick from a large adult.

Avoid thin or loosely woven mesh marketed as “security” but untested. True mesh protection is engineered, not decorative.

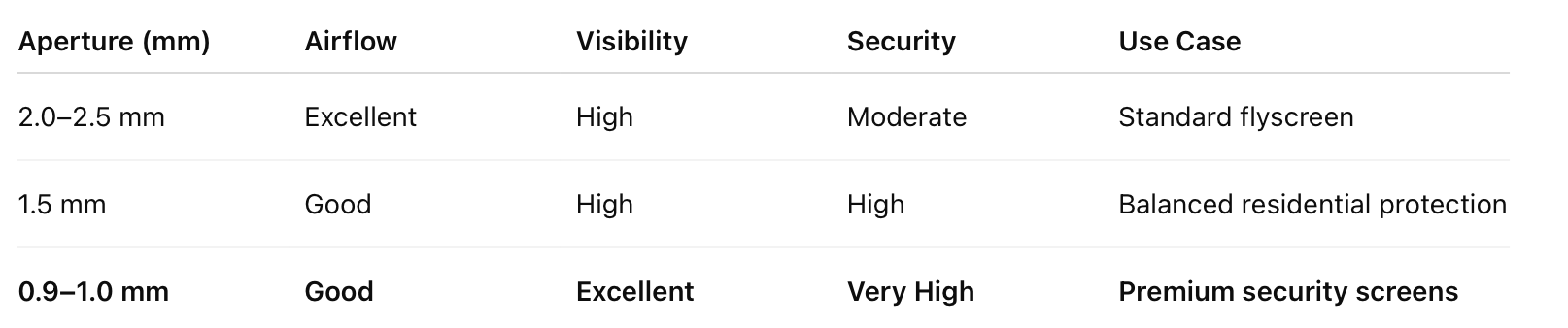

Aperture Size: Finding the Sweet Spot

Aperture size refers to the open area between the wires — measured in millimeters.

Smaller apertures block more intrusion attempts (knife, crowbar, or ember attack) without noticeably restricting airflow.

Mesh with apertures below 1.2 mm also qualifies as ember-resistant under AS3959 wildfire standards.

Coating and Finish Quality

The finish determines how long your mesh stays clean, strong, and visually appealing.

Powder-Coating

Premium powder coatings resist UV fade, scratches, and salt corrosion.

Look for polyester or fluoropolymer coatings rated for marine exposure.

Avoid painted finishes — they chip easily and allow rust to creep underneath.

Color Matching

Most manufacturers offer black, bronze, and white finishes.

Boss Security Screens custom-powder coats mesh and frames to match your window trim, making protection nearly invisible from the street.

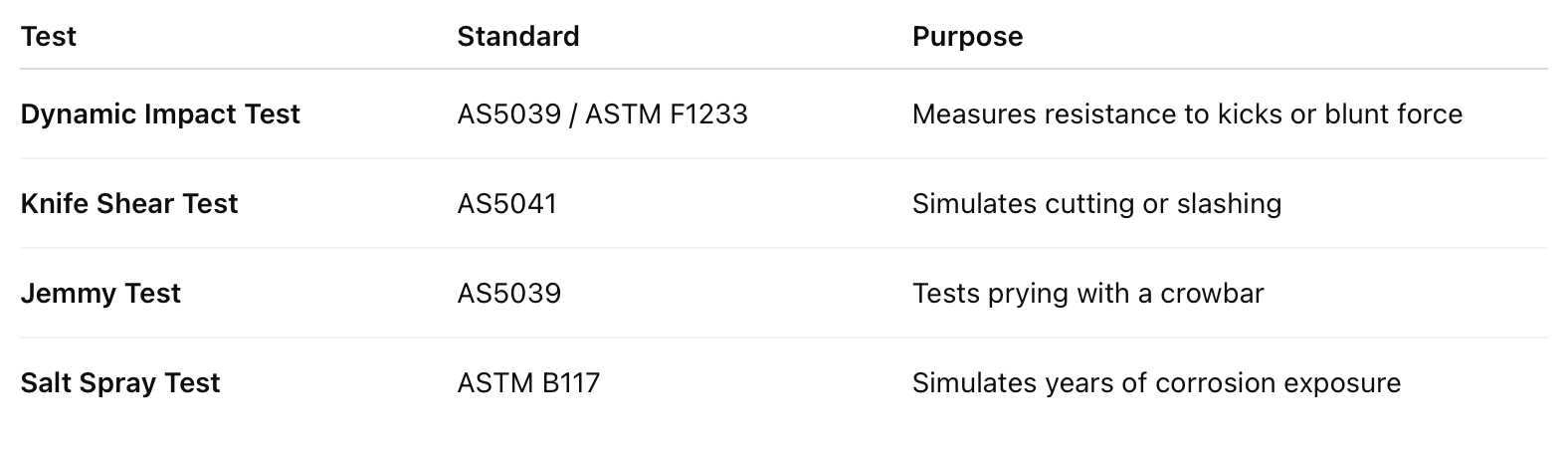

Testing and Certification

Before you buy, verify compliance with international test standards.

A properly engineered mesh door should pass:

Simulates years of corrosion exposure

Manufacturers who can’t provide documentation likely sell decorative or insect-grade mesh, not security-rated products.

Real-World Performance: Coastal vs. Desert Environments

Coastal Example – San Diego, CA:

Homeowners who installed 304 stainless mesh saw surface oxidation after three years due to ocean air.

316 marine-grade mesh remained flawless after six years with only light washing.

Desert Example – Las Vegas, NV:

Dust and temperature swings caused aluminum mesh to warp slightly and detach from frames.

Boss’s 316 mesh remained taut and intact even after extreme heat cycles (120°F days to 40°F nights).

Expert Insight

According to Boss Security Screens, mesh selection determines more than just strength — it defines comfort.

“Our clients expect airflow, light, and design harmony,” their engineering team explains.

“We use marine-grade mesh because it doesn’t just stop burglars — it survives time, weather, and sun.”

Maintenance Tips for Longevity

Even marine-grade mesh benefits from minimal care:

Hose down screens twice per year (quarterly in coastal zones).

Avoid abrasive cleaners.

Check frame fasteners annually for tightness.

Proper care can extend life expectancy to 30 years or more.

Conclusion

When choosing mesh for your security door, think beyond “metal.”

Choose a marine-grade stainless-steel mesh (316) with certified testing, tight aperture, and professional coating.

It’s the difference between protection that looks good for a season — and protection that lasts a lifetime.

Strong mesh is the heart of every true security door.

Choose wisely, and it will quietly protect your home for decades.